The construction and architectural industry continues to evolve with innovative glazing solutions that enhance both energy efficiency and aesthetic appeal. Power glass technology represents a significant advancement in building materials, offering architects and developers unprecedented control over thermal performance and light management. As building codes become more stringent and sustainability requirements increase, understanding the capabilities of modern power glass systems becomes essential for successful project implementation.

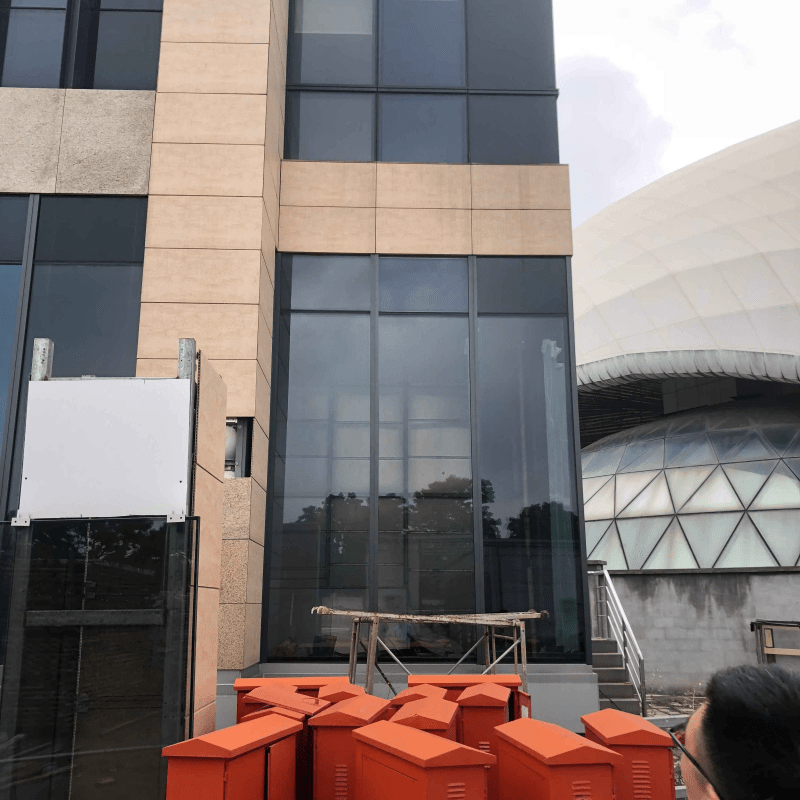

Modern power glass installations incorporate advanced coating technologies and multi-layer configurations that dramatically improve building performance metrics. These systems provide superior insulation properties while maintaining excellent optical clarity, making them ideal for commercial and residential applications. The integration of power glass into contemporary building designs enables architects to create expansive glazed facades without compromising energy efficiency standards.

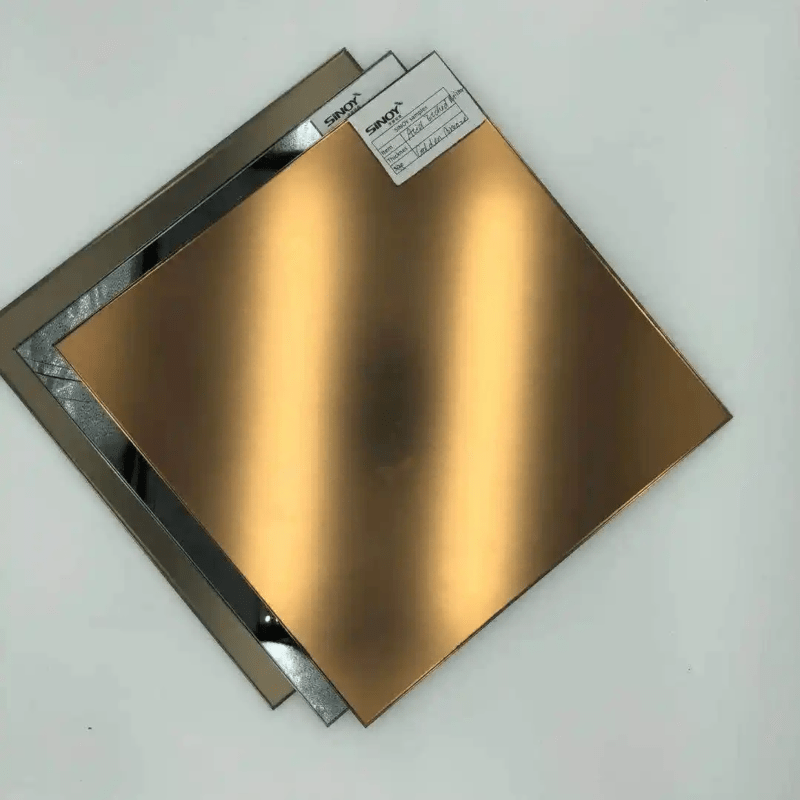

Advanced Coating Technologies in Power Glass Systems

Low-E Coating Applications

Low-emissivity coatings represent the foundation of effective power glass performance, utilizing microscopic metallic layers to control radiant heat transfer. These specialized coatings allow visible light to pass through while reflecting infrared radiation, significantly reducing cooling loads during summer months. The precision application of low-E coatings on power glass surfaces creates an invisible barrier that maintains comfortable interior temperatures year-round.

Triple silver low-E coatings offer enhanced performance compared to traditional single or double silver configurations. The multiple silver layers in power glass units provide superior selectivity between visible light transmission and solar heat gain control. This advanced coating technology enables buildings to maximize natural daylight while minimizing unwanted thermal gains, resulting in substantial energy savings and improved occupant comfort.

Selective Transmission Properties

The selective transmission characteristics of power glass allow precise control over different wavelengths of solar radiation. Infrared wavelengths responsible for heat generation are effectively blocked, while visible light wavelengths pass through unimpeded. This selective approach ensures that power glass installations maintain bright, naturally lit interior spaces without the associated thermal penalties.

Advanced spectral control in power glass systems enables customization for specific geographic locations and building orientations. Northern exposures may utilize different coating configurations compared to southern facades, optimizing performance based on solar angle variations and seasonal changes. The flexibility of power glass technology allows architects to tailor solutions for maximum efficiency across diverse climatic conditions.

Thermal Performance Characteristics

U-Value Optimization

The thermal transmittance or U-value of power glass units directly impacts building energy consumption and compliance with energy codes. Modern power glass assemblies achieve exceptionally low U-values through strategic gas fills and advanced spacer technologies. Argon or krypton gas fills between glass panes provide superior insulation compared to air-filled units, reducing conductive heat transfer.

Warm-edge spacer systems in power glass configurations minimize thermal bridging at the perimeter seal, further improving overall thermal performance. These specialized spacers utilize materials with low thermal conductivity, preventing heat transfer around the edges of insulated glass units. The combination of advanced coatings, gas fills, and warm-edge spacers enables power glass systems to exceed stringent energy efficiency requirements.

Solar Heat Gain Control

Solar Heat Gain Coefficient (SHGC) values in power glass systems can be precisely tuned to match specific building requirements and climate zones. Lower SHGC values benefit cooling-dominated climates by reducing solar heat gain during peak summer conditions. Conversely, moderate SHGC values may be preferred in heating-dominated regions to capture beneficial winter solar gains while maintaining summer comfort.

The dynamic range of SHGC options available in power glass products enables architects to optimize facade performance for different building orientations. East and west-facing surfaces typically require lower SHGC values due to low-angle sun exposure, while north-facing installations may accommodate higher values for maximum daylight admission. This flexibility allows power glass systems to provide customized solutions for complex building geometries.

Installation and Design Considerations

Structural Requirements

Power glass installations require careful consideration of structural loading and support systems to ensure long-term performance and safety. The weight of multi-pane power glass units exceeds that of single glazing, necessitating appropriate framing and anchoring systems. Structural calculations must account for wind loads, seismic forces, and thermal expansion to prevent stress concentrations that could compromise the glazing system.

Curtain wall and window frame selection plays a crucial role in maximizing power glass performance potential. Thermally broken frames prevent conductive heat transfer that could bypass the insulating properties of the glazing unit. The integration of power glass with high-performance framing systems creates a comprehensive thermal envelope that meets or exceeds current energy efficiency standards.

Quality Control Protocols

Manufacturing quality control for power glass products involves rigorous testing and inspection procedures to ensure consistent performance characteristics. Coating uniformity, seal integrity, and optical clarity must meet strict tolerances to maintain the specified thermal and visual properties. Advanced quality assurance protocols include spectral analysis, thermal cycling tests, and durability assessments under accelerated aging conditions.

Installation quality control procedures for power glass systems focus on proper handling, storage, and placement techniques to prevent damage or performance degradation. Protective films and specialized lifting equipment prevent coating damage during transportation and installation. Proper glazing compound application and structural glazing techniques ensure long-term weather seal integrity and thermal performance maintenance.

Economic Benefits and ROI Analysis

Energy Cost Reduction

The implementation of power glass systems generates substantial energy cost savings through reduced HVAC loads and improved building envelope performance. Detailed energy modeling demonstrates that power glass installations can reduce annual energy consumption by twenty to forty percent compared to conventional glazing systems. These savings compound over the building lifecycle, providing significant economic benefits to building owners and operators.

Peak demand reduction represents an additional economic benefit of power glass technology, as improved thermal performance reduces maximum cooling loads during extreme weather conditions. Utility demand charges often constitute a substantial portion of commercial energy costs, making peak load reduction particularly valuable for large commercial and institutional buildings. Power glass systems help minimize these demand charges while maintaining optimal interior comfort conditions.

Lifecycle Cost Analysis

Comprehensive lifecycle cost analysis reveals that power glass systems provide favorable returns on investment despite higher initial costs compared to standard glazing products. The extended service life of quality power glass installations, combined with ongoing energy savings and reduced maintenance requirements, creates positive cash flow over the building lifecycle. Additionally, power glass systems may qualify for energy efficiency incentives and tax credits that improve project economics.

Market value enhancement represents an often-overlooked benefit of power glass installations, as energy-efficient buildings command premium rents and sale prices in competitive real estate markets. Green building certifications such as LEED and ENERGY STAR recognize the contributions of high-performance glazing systems, adding measurable value to property portfolios. The growing emphasis on sustainability in commercial real estate makes power glass systems an increasingly attractive investment.

Environmental Impact and Sustainability

Carbon Footprint Reduction

Power glass technology contributes significantly to building decarbonization efforts through dramatic reductions in operational energy consumption and associated greenhouse gas emissions. The superior thermal performance of power glass systems reduces reliance on fossil fuel-powered HVAC equipment, directly lowering carbon footprints. Life cycle assessments demonstrate that the environmental benefits of power glass installations far exceed the embodied energy required for manufacturing and installation.

The durability and longevity of power glass systems further enhance their environmental credentials by reducing replacement frequency and associated waste streams. Quality power glass installations maintain their performance characteristics for decades, minimizing the need for premature replacement due to coating degradation or seal failure. This extended service life reduces the overall environmental impact per unit of building area served.

Sustainable Manufacturing Processes

Modern power glass manufacturing incorporates sustainable practices including energy-efficient production processes and recycled content utilization where technically feasible. Advanced coating deposition techniques minimize material waste while ensuring consistent performance characteristics across production runs. The industry continues to develop more environmentally friendly manufacturing methods that reduce energy consumption and emissions during the production process.

End-of-life recyclability considerations are increasingly important in power glass system design and specification decisions. While specialized coatings may complicate recycling processes, the glass substrate itself remains highly recyclable through standard glass recycling channels. Ongoing research focuses on developing power glass technologies that maintain high performance while facilitating easier recycling and material recovery at end of service life.

Future Developments and Technology Trends

Smart Glass Integration

The convergence of power glass technology with smart glass capabilities represents an exciting frontier in building envelope innovation. Electrochromic and thermochromic technologies can be integrated with traditional power glass coatings to create dynamic systems that respond automatically to changing environmental conditions. These intelligent power glass systems optimize performance in real-time, maximizing energy efficiency and occupant comfort throughout varying seasonal and daily conditions.

Internet of Things (IoT) integration enables power glass systems to communicate with building management systems for coordinated environmental control strategies. Sensors embedded within or adjacent to power glass installations can monitor thermal performance, solar conditions, and occupant preferences to optimize automated shading and climate control systems. This integration creates truly responsive building envelopes that adapt continuously to optimize performance and comfort.

Advanced Coating Technologies

Emerging coating technologies promise even greater performance capabilities for next-generation power glass products. Nanostructured coatings and advanced material compositions are being developed to achieve unprecedented combinations of visible light transmission and thermal control. Research into spectrally selective coatings continues to push the boundaries of what is possible with power glass technology.

Durability enhancements represent another key area of power glass technology development, with new coating formulations designed to withstand harsh environmental conditions while maintaining optimal performance over extended periods. Anti-soiling coatings and self-cleaning technologies are being integrated into power glass systems to reduce maintenance requirements and preserve optical clarity throughout the service life.

FAQ

What makes power glass different from standard insulated glass units

Power glass incorporates advanced low-emissivity coatings and specialized gas fills that provide superior thermal performance compared to standard insulated glass. The selective transmission properties of power glass allow visible light to pass through while blocking infrared radiation, resulting in better energy efficiency and occupant comfort. Standard insulated glass units lack these advanced coatings and typically use air fills, providing minimal thermal enhancement over single-pane glazing.

How does power glass perform in different climate zones

Power glass systems can be customized for optimal performance across diverse climate zones through appropriate coating selection and configuration adjustments. Cooling-dominated climates benefit from power glass with lower solar heat gain coefficients to minimize unwanted thermal gains. Heating-dominated regions may utilize power glass configurations with moderate solar heat gain coefficients to capture beneficial winter solar energy while maintaining thermal efficiency. Mixed climates require balanced power glass specifications that optimize performance across seasonal variations.

What maintenance requirements apply to power glass installations

Power glass systems require minimal maintenance beyond standard glazing cleaning procedures, as the advanced coatings are applied to interior surfaces protected from weather exposure. Regular inspection of seals and frames ensures continued thermal performance and prevents moisture infiltration. Professional cleaning with appropriate techniques and materials preserves coating integrity and optical clarity. Most power glass installations maintain their performance characteristics for decades with proper care and maintenance.

Can existing buildings be retrofitted with power glass technology

Existing buildings can often accommodate power glass retrofits, though structural evaluations may be necessary to ensure adequate support for the increased glazing unit weight. Frame compatibility must be assessed to determine whether existing systems can accommodate the thickness of power glass units. Retrofit projects provide excellent opportunities to dramatically improve building energy performance and occupant comfort while updating the aesthetic appearance of aging facades. Professional assessment ensures that retrofit installations achieve optimal performance and compliance with current building codes.