چالش های آب و هوا گرمسیری و اثربخشی پوشش

در مناطق استوایی، رطوبت بالا و تابش فوق بنفش شدید، چالشهای بزرگی برای ظاهر و طول عمر شیشههای سنتی ایجاد میکنند. در این مناطق، محکمیت شیشههای سنتی کاهش مییابد و معمولاً سریعتر خرج میشوند. با این حال، پوششهای Low-E (کم-emi) و بازتابی به طور قابل توجهی کارآمد هستند. آنها دیدپذیری بهتری فراهم میکنند و با محافظت از شیشه در برابر اشعههای مضر فوق بنفش، کمک میکنند تا شیشه برابر با اثرات آسیبزای خورشید مقاومت کند. به عنوان مثال، پوششهای کم-emi جریان گرما را به داخل ساختمانها کاهش میدهند تا محیط داخلی آرامتری ایجاد شود و طول عمر شیشه میتواند تا ۲۰٪ افزایش یابد. نظر کارشناسان این است که ممکن است تا ۴۰٪ از گرماهای خورشیدی را کاهش دهند، و این موضوع در حفظ دمای مناسب داخلی و کاهش هزینههای انرژی در مسکنهای مناطق استوایی حائز اهمیت است.

عملکرد در محیط خشک و مقاومت در برابر تابش فوق بنفش

منطقههای بیابانی مشکلات خاصی دارند که شامل دمای بسیار بالا و گرد و غبار مداوم است که میتواند به سرعت به سطوح شیشهای بدون پوشش حمله کند. شیشه در این کاربردها، اگر بدون پوشش باقی بماند، عرضه تخریب سریع قرار میگیرد. پوششهای مقاوم به فرابنفش یک جایگزین قوی هستند، به ویژه پوششهای مقاوم به فرابنفش طراحی شده برای آب و هوای خشک و سخت. این پوششها طراحی شدهاند تا تخریب ناشی از فرابنفش را به طور قابل ملاحظهای کاهش دهند و بنابراین ساختار و ظاهر هر سطح شیشهای را حفظ کنند. آمارهایی که توسط تولیدکنندگان برجسته پوشش ارائه شده، نشان میدهد که برخی از پوششهای مقاوم به فرابنفش مورد استفاده قرار گرفته، میتوانند به اندازه ۲۵٪ به طول عمر شیشه نسبت به شیشه بدون پوشش اضافه کنند. پارامترهای عملکرد نیز کاهش قابل توجهی در مطالبات ضمانت را نشان میدهد، که به مزایای بلندمدت کسب و کار از استفاده از پوششهای پیشرفته برای آب و هوای خشک اشاره میکند.

پایداری در برابر خوردگی نمک در آب و هوای ساحلی

دشمن دیگری سطوح شیشهای در مناطق ساحلی، جایی که رطوبت بالا و آب شور مشکلات دوگانهای ایجاد میکند. این عوامل میتوانند به طور سریع ثبات شیشهای که پوشش ندارد را در طول زمان تحت تأثیر قرار دهند. چنین شرایطی به طور مؤثر با استفاده از شیشههای پوششدار ضد زنگ خوردن کاهش یافته یا حذف میشوند. این پوششهای سفارشی طراحی شدهاند تا برابر زنگ زنگی ناشی از نمک مقاومت کنند و میتوانند طول عمر کلی تجهیزات دریایی و وسایل نقلیه را افزایش دهند. برای مثال، استفاده از شیشههای پوششدار در مناطق ساحلی در مطالعات موردی اخیر ثابت شده است که عملکرد بهتری دارند و نیاز به نگهداری کمتری دارند. در کاربردهای ساحلی، مزایای اضافی قابلیت تحمل شیشههای پوششدار نسبت به شیشههای بدون پوشش میتواند تا 30٪ باشد.

روشهای تنظیم دما در مناطق معتدل

در مناطق معتدل، جایی که آب و هوا طی سال تغییر میکند و نیاز به گرما و سرمایش ساختمانها را تحت تأثیر قرار میدهد، استفاده از شیشه پوششداده شده یک عامل کلیدی در کنترل حرارتی و افزایش ورود نور طبیعی است. پوششهایی مثل Low-E با محدود کردن از دست رفتن گرما در زمستان و بلوک کردن بخش زیادی از گرما از خورشید در ماههای گرم، صرفهجویی در انرژی را ترویج میدهد. این ویژگی 2-در-1 امکان صرفهجویی در زمان و انرژی برای خانوادهها و استفاده تجاری را فراهم میکند که برنامهریزی میکنند تا هزینههای گرما و سرمایش محیط زندگی خود را کاهش دهند. گزارش شده است که ساختمانهایی که از CoCs استفاده میکنند، صرفهجویی معناداری در مصرف انرژی طی سال تا 15٪ داشتهاند و همچنین به افزایش راحتی حرارتی داخلی کمک میکنند، کارآمدی این پوشش را در آب و هوای معتدل نشان میدهد.

با سفارشیسازی نصب شیشه به چالشهای آب و هوای خاص، میتوانیم بهرههای بیشتری از پوششهای نوآورانه بدست آوریم، که منجر به راهحلهای پایدارتر و ارزانتر میشود.

بهینهسازی راهکارهای کاربرد شیشه پوششداده

همخوانی انواع پوشش با نیازهای محیطی

پوشش مناسب برای شیشه میتواند به طور قابل توجهی عملکرد آن را در شرایط محیطی خاص بهبود ببخشد. انواع مختلف پوشش، از جمله پوششهای low-E (کم تابش)، رنگی و بازتابی، توابع خاصی دارند و میتوانند بر اساس آب و هوای خاصی اعمال شوند. پوششهای low-E در همه نوع آب و هوای سرد یا گرم، علاوه بر کاهش اتلاف انرژی، در آب و هوای سرد کمک میکنند تا گرما وارد شیشه نشود. پوششهای رنگی کمک میکنند تا نور چشمآزار و حرارت ناشی از خورشید کاهش یابد و پوششهای بازتابی ضمن افزایش حریم خصوصی، از تابشهای UV محافظت میکنند. بررسی جامعی در محیط ساختمان نشان داد که انتخاب پوشش مناسب، علاوه بر بهبود عملکرد انرژی، دوره عمر مفید محصولات شیشه را نیز افزایش میدهد. برای مقایسه آسان نحوه کار این پوششها بر اساس محیط، جدول زیر را ببینید:

| نوع پوشش | بهینه را ایجاد کنید | مزایای کلیدی |

|---|---|---|

| Low-E | آب و هوای سرد/گرم | کاهش انتقال گرما، بهبود عایقسازی |

| رنگدانه ای | مناطق خورشیدی | کاهش تابش نور، حفاظت از فروتن |

| عایق نور | نیازهای شهری/خصوصی | افزایش حریم خصوصی، بازتاب فروتن |

رویکردهای پیادهسازی تجاری نسبت به مسکونی

شیشههای پوششدار در کاربردهای مسکونی و تجاری تفاوتهای بسیار زیادی دارند. برای پروژههای تجاری، اغلب سیستمهای پوشش صنعتی مقاومتری مورد نیاز است که بتوانند به خوبی به سطوح بزرگتر چسبندگی داشته باشند و در برابر عوامل محیطی مقاومت طولانیتری از خود نشان دهند. به عنوان مثال، ساختمانهای بلند با استفاده از پوششهای خاصی میتوانند از گرمایش شدید ناشی از تابش خورشید با حفظ شفافیت نوری بالا جلوگیری کنند. در مقابل، کاربردهای مسکونی بیشتر به دنبال بهبود عایقبندی و افزایش آسایش هستند و تمایل دارند پوششهایی را انتخاب کنند که در صرفهجویی در انرژی کمک کننده باشند. داستان موفقیت جالب توجه، شامل یک مجتمع تجاری بزرگ است که با تغییر به شیشههای پوششدار با عملکرد بالا، هزینههای انرژی خود را تا ۳۰٪ کاهش داد و اثربخشی این سیستم را حتی در بزرگترین کاربردها ثابت کرد. بازخوردهای حاصل از این نصبها اغلب بر لزوم وجود راهحلهای سفارشی برای هر بخش به منظور بهرهوری بیشتر و افزایش اقتصادی بودن سیستم تأکید دارند.

نگهداری بلندمدت برای مروناکی در برابر آب و هوا

نگهداری از عملکرد شیشه پوشش داده شده تحت آب و هوای مختلف ضروری است. نگهداریهایی مانند تمیز کردن منظم و بازرسیها برای حفظ وضعیت محافظتکننده پوشش در برابر تنشهای محیطی استفاده میشود. بر اساس خبرگان، باید برنامهای دوبار در سال دنبال شود تا سرخوردگی و خستگی را ارزیابی کرده و شیشه پوشش داده شده را مثل جدید نگاهداری کرد. روشهای تشخیصی مانند آزمون فتوتخرابی و بررسی بصری برای شناسایی زودهنگام این مشکلات حیاتی است. نظرسنجان صنعت همیشه تاکید میکنند که تمیز کردن شیشه پوشش داده شده اهمیت دارد چرا که در بلندمدت، جایگزینی برنامههای نگهداری خارجی بیشتر از هزینه پرداخت آنها خواهد بود. این تکنیک رو به جلو، عاملی است که باعث میشود کاربردهای شیشه عملکرد عالی را در تمام انواع محیط فراهم کند و عملکرد قوی ارائه دهد.

پوشش شیشه آنلاین EA: راهحل سازگار با آب و هوا

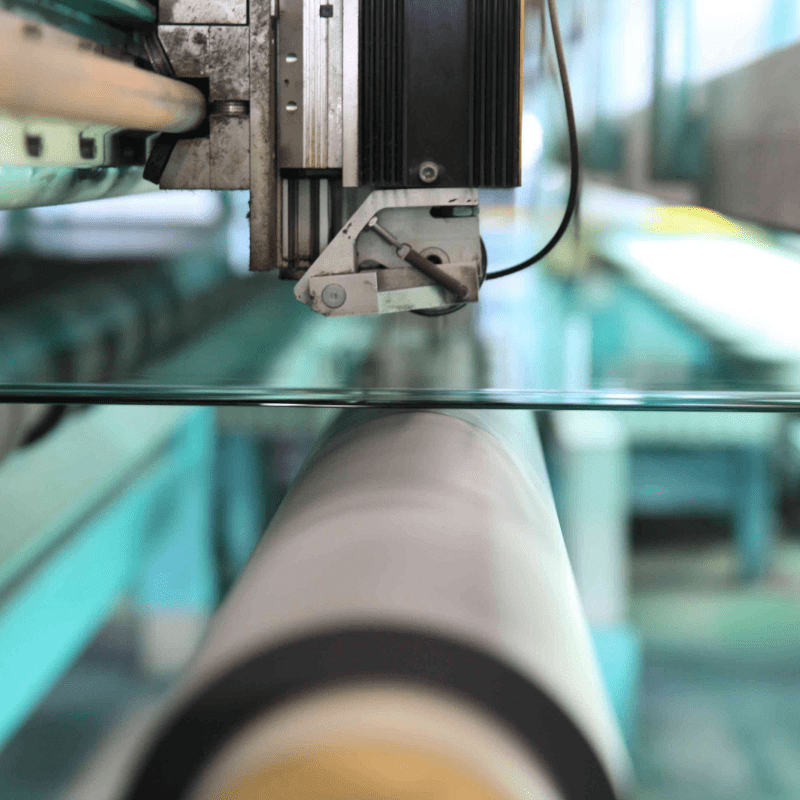

تکنولوژی پایرولیتیک برای مقاومت در برابر آب و هوای حدی

تکنولوژی پوشش پیرولیتیک همه چیزها را در عملکرد شیشه تغییر میدهد، به ویژه زمانی که به آب و هوای استوار میپردازیم. این روش جدید و جالب - پوشاندن ماده قبل از آنکه شیشه آنیل شود - پوشش را به گونهای محکم بسته میکند که نمیتواند جدا شود. به این ترتیب، مقاومت بالاتری فراهم میکند و از خارج شدن پوشش جلوگیری میکند، بنابراین صدمات حرارتی و تأثیرات محیط را تحمل میکند. این نوع مقاومت برای مواردی مثل پنجرههای کمپر RV مناسب است، زیرا باید با طیف گستردهای از دماها و محیطها مبارزه کند. این ادعاها توسط سازمانهای آزمایشی به طور مستقل آزمایش و اعتبارسنجی شدهاند و با بررسیهای متعدد عملکردی که نشان میدهد پوشش قادر به مقابله با نیازهای شرایط آب و هوای شدید است، همزمان عمل و سلیقه کلی خود را حفظ میکند.

دادههای عملکرد چند اقلیمی و انعطافپذیری کاربرد

Glas با کوچکسازی آنلاین EA گستردگی عالی در مناطق آب و هوای مختلف را ارائه میدهد، با پایگاه دادهای محکم از عملکرد برای حمایت از تعداد زیادی پروژههای تکمیلشده. به دلیل توانایی گلس کوچکسازی شده برای ساخت IG یا لامینات بدون نیاز به حذف لبه، این گلس کوچکسازی شده میتواند به طور هماهنگ در بسیاری از محیطهای معماری جایگزین شود. این انعطافپذیری به طراحان اجازه میدهد تا هدفهای عملکردی و زیباییشناسی مورد نظر خود را در حالی که چالشهای محیطی خاص محلی را در آب و هواهای مختلف بررسی میکنند، به دست آورند. مطالعات و گزارشهای پیشبینی نشان میدهند که ارزش بازار برای ویژگیهای قابل تنظیم چند آب و هوا در حال افزایش است. بهبود مناسب بودن برای چند آب و هوا ارزش خاص را افزایش میدهد و کل نمره پایداری را بالا میبرد، بنابراین این نوع سیستم سرمایهگذاری ایدهآلی برای خانهداران و کسبوکارهای رو به جلو است.

افزایش عملکرد از طریق نوآوری در پوشش

پیشرفتهای پوشش شیشه مایع در کنترل رطوبت

با استفاده از پوششهای شیشهای مایع که به یک تغییر دهنده در کنترل سطح رطوبت در ساختمانهای شیشهای تبدیل شده است. این توسعههای جدید منجر به ایجاد یک ساختار قوی و چگال ضد آب شده است که علیه تشکیل قارچ و فساد محافظت میکند و انتقال رطوبت را جلوگیری میکند. نانوتکنولوژی روی شیشه به صورت مولکولی عمل میکند و یک سطح محافظتکننده و غیرچسبنده به شیشه ارائه میدهد که علیه تراکم کلسیم و آلودگیهای عمومی محافظت میکند. این محصول یک راهحل قوی برای آسیبرسیدگی شیشه و کیفیت هوا در محیطهای مرطوب است. این توسعهها توسط متخصصان از سازمانهای پژوهشی برجسته جهانی پشتیبانی شده است که کارآیی آنها در شرایط مرطوب را تأیید کردهاند.

راهحلهای سطح متنوع برای محیطهای تخصصی

راهحلهای سطحی با طرحها و متنها نیز در حال تعریف مجدد گlass چگونه در کاربردها و محیطهای منحصر به فرد استفاده میشود – مانند حمام، همانطور که از رواج دربهای شور جدید دیده میشود. این مناطق علاوه بر افزودن گرفتگی و دیدپذیری نیز ویژگی ایمنی آسانی هستند. خلاقیت و مهارت فنی در پوششهای glass متنی زیبایی و جالبترینها را در طراحی اضافه میکند و همچنین بسیار عملکردی هستند. glass متنی بسیار قوی و قابل اتکا است بخاطر تکنیکهای تولید مدرن. این راهحلها بسیار مورد استقبال کاربران قرار گرفتهاند، همانطور که صدها نظر مثبت و گواهی میتوانند به آن اشاره کنند، نشان دهنده هماهنگی بین سبک و ایمنی در کاربردهای واقعی است.